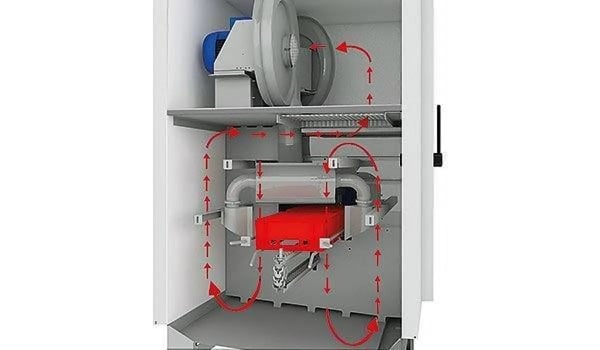

Blow off units are available as a direct option on the Elpress crate washers. Load carriers are blown off in the blow off unit by power stainless steel fans. The intelligent Elpress design heats the air (partly through recirculation) up to approx. 50 °C, which results in an even better blowing capacity.

Advantages

After being cleaned the crates are transported by the extended chain from the washer into the blow off zone. The air blades produce a powerful ‘cutting’ air flow that blows excess water off the crates. The motors are safely hidden away in the stainless steel enclosure which is added to the washer.

After being cleaned the crates are transported by the extended chain from the washer into the blow off zone. The thermocell enclosure delivers a maximum heat and sound isolation.

Just like the washing systems, our blow off units consist of various zones. The arrangement into compartments prevents the removed moisture from being blown back on to the load carriers. The removed moisture is transported outside by a venting system.

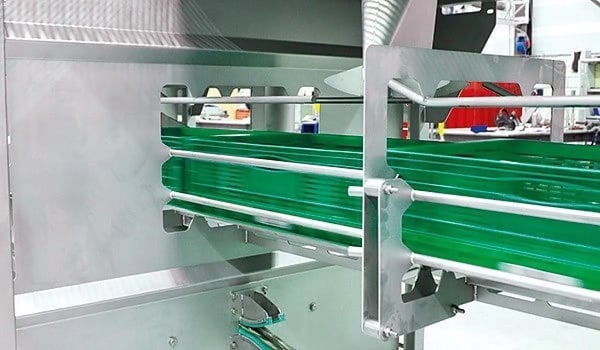

Because we make use of stainless steel pipes with a large diameter, less resistance is created when the air passes through the blower outlets. Since the fans are placed at the top of the blow off units, the water on the underside of the load carriers can be blown away by the high air velocity.

The specifically shaped blower outlets cause the supplied air to scrape over the object passing through the blower like an ‘air blade’. The blower outlets are aligned to treat all sides of the load carriers.

The blow off units are constructed with an insulated housing (stainless steel or Foodsafe). This retains the temperature produced during operation, which ensures that the load carriers dry better afterwards. The insulation also contributes to a reduction in the noise level.

Do you want a no-obligation discussion about practical provisions that you can implement within your company? Then schedule an appointment with me.