The crate washers from Elpress make sure that all the dirt on the crate, such as proteins, blood residues, fasts, sticker and glue residues and dried-on dirt, is removed in a single wash cycle. This also removes the dirt that is invisible to your employees.

Open brochure Start Crate washer calculatorAdvantages

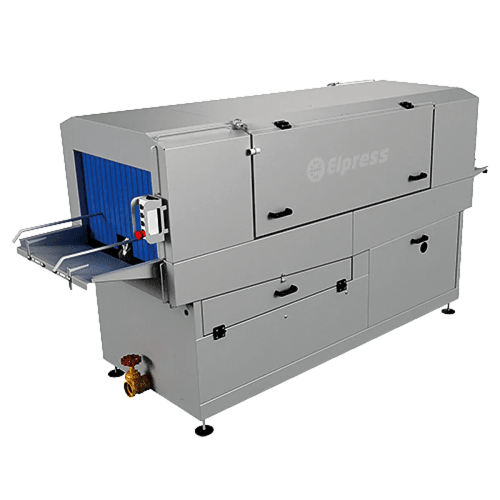

The EKW crate washers are made of solid stainless steel sheets and sections and are placed on adjustable feet. The washing tunnel is provided with hinged doors. If a door is opened during cleaning, the installation stops immediately. The crates are transported through the system by a plastic transport chain. The rinse arches are provided with a large number of plastic click-nozzles. The EKW crate washers are suitable for crates with maximum dimensions of 600 x 400 x 300 mm (LxWxH).

Advantages

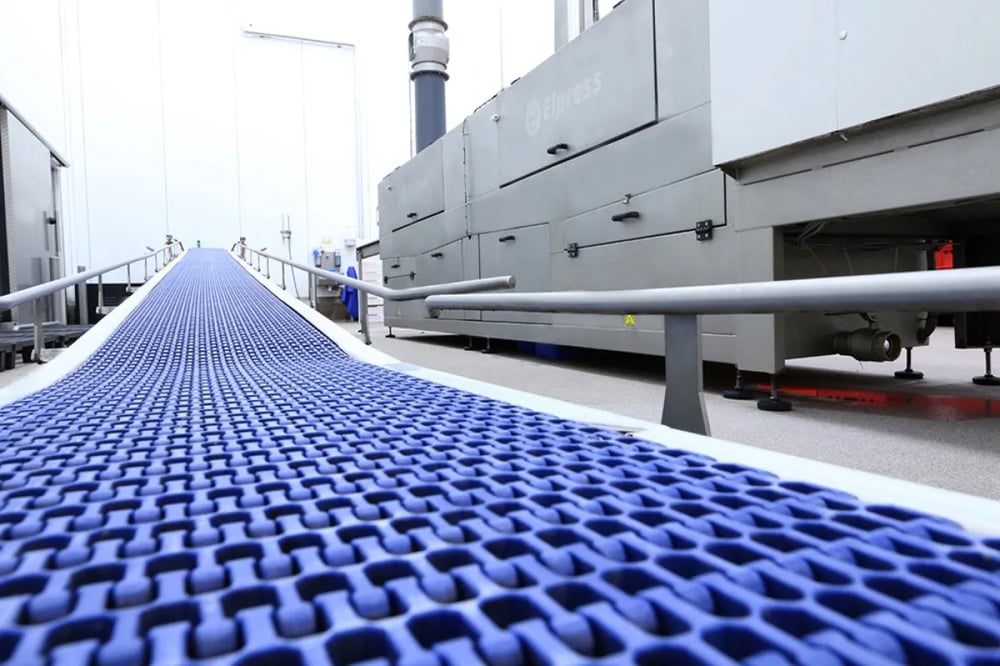

The crates are transported into the EKW crate washer by a plastic transport chain. The transport chain ensures that the crates are moved through the various zones.

As already mentioned, the crate washer has different (optional) zones. We inform you about each zone here:

A crate washer is available in several versions and with various additional options. In this way, the crate washer can always be adapted to the specific requirements and capacity of your business.

Max. 170 crates per hour

Main wash and rinse zone

Article number: 83101125

Max. 400 crates per hour

Main wash and rinse zone

Article number: 83101150

Max. 560 crates per hour

Main wash and rinse zone

Article number: 83101350

Max. 800 crates per hour

Pre wash, main wash and rinse zone

Article number: 83101650

Max. 960 crates per hour

Pre wash, main wash and rinse zone

Article number: 83101750

Max. 1120 crates per hour

Pre wash, main wash and rinse zone

Article number: 83101850

Max. 1650 crates per hour

Pre wash, main wash and rinse zone

Article number: 83101950

Max. 2240 cates per hour

Main wash and rinse zone

Article number: 83101855

Max. 3360 crates per hour

Main wash and rinse zone

Article number: 83101955

Max. 4480 crates per hour

Main wash and rinse zone

Article number: 83101985

Max. 5600 crates per hour

Main wash and rinse zone

Article number: 83101995

Max. 330 crates per hour, based on a crate length of 950 mm and dwell time of 50 seconds.

Pre-wash zone and rinse zone

Article number: 83102805

Max. 500 crates per hour, based on a crate length of 950 mm and dwell time of 50 seconds.

Pre-wash zone, main wash zone and rinse zone

Article number: 83102815

Max. 660 crates per hour, based on a crate length of 950 mm and dwell time of 50 seconds.

Pre-wash zone, main wash zone and rinse zone

Article number: 83102825

Max. 820 crates per hour, based on a crate length of 950 mm and dwell time of 50 seconds.

Pre-wash zone, main wash zone l, main wash zone ll and rinse zone

Article number: 83102835

Max. 1000 crates per hour, based on a crate length of 950 mm and dwell time of 50 seconds.

Pre-wash zone, main wash zone l, main wash zone ll and rinse zone

Article number: 83102845

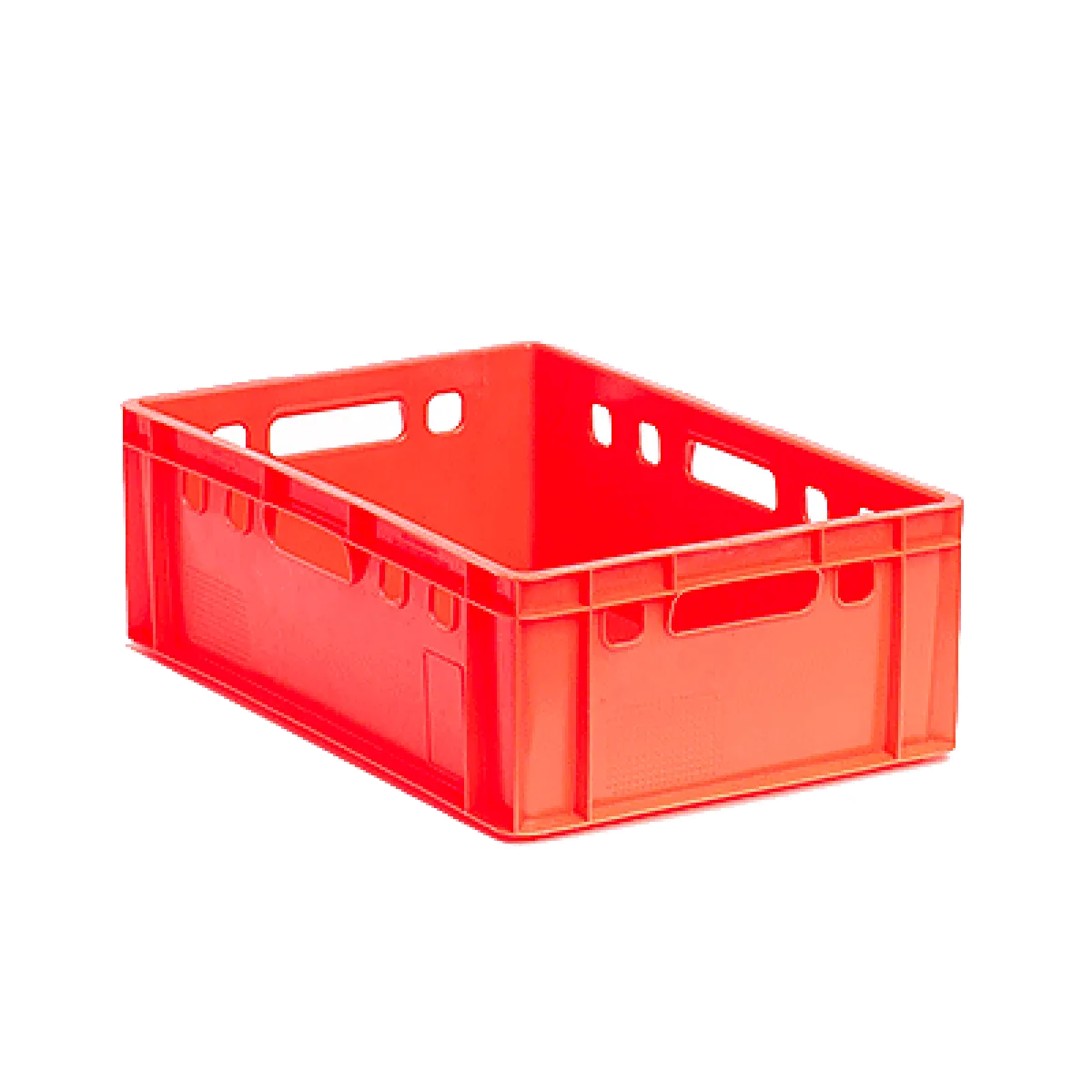

Load carriers come in different shapes and sizes. CBL-crates, E2-crates and fish crates. It is often possible to clean different types of crates in a standard crate washer. But it is important that the side of the crates that are put into the washer is reasonably uniform. So that the different types of crate run smoothly over the washer's guides. It is therefore important that this side has approximately the same width for all the crates, and that they do not differ too much in their design (the presence of indentations or cut outs). Read more here about different types of crate in a crate washer.

The EKW crate washers are also available in a double version. By adding a second line, you double the capacity of the crate washer. These double versions are constructed, just as single versions, of solid stainless steel sheets and sections, and are placed on adjustable feet. The crates are transported through the system by a plastic transport chain.

The functionalities of these crate washers are the same as the single versions. Characteristic of this line are the sloping roofs that ensure no water remains on the roof of the crate washer. With an advanced control system, you have better insights into the process and communication with the crate washer.

Elpress not only supplies carefully designed crate washers but also works with you to simplify and optimise your washing processes. Our certified crate washers are environmentally friendly and efficient, which saves you money. Water and energy are used sparingly with no detrimental effects on the cleaning itself. Features include:

As a customer, you therefore always benefit from a user-friendly, innovative, durable system that meets your specific requirements and comes with an attractive price tag. Are you interested in the possibilities, or would you like to know more about our crate washers? Then feel free to get in touch with us.

scwy76.webp?width=1000&height=667&name=tmp010-IMG_5346_2-2%20(1)scwy76.webp)

The EKW crate washers are made of solid stainless steel sheets and sections and are placed on adjustable feet. The washing tunnel is provided with hinged doors. If a door is opened during cleaning, the installation stops immediately. The crates are transported through the system by a plastic transport chain. The rinse arches are provided with a large number of plastic click-nozzles. The EKW crate washers are suitable for crates with maximum dimensions of 600 x 400 x 300 mm (lxwxh).

Advantages

● Low energy consumption

● Easy-to-adjust click-nozzles

● Made from stainless steel

● Optional one-person operation

Read here everything you have to think about when buying a crate washer.

The new visual inspection system makes it possible to check whether a crate has exited the crate washer in a clean and intact state. Five cameras are used to thoroughly inspect the inside and outside of the crates. Photos are taken at several points and the system can tell within just one second whether the crate is clean as well as intact.

Advantages

The ELB crate washers are made from rugged stainless steel plates and profiles. These line machines are specially designed for cleaning live bird crates. These are crates that are used for the transportation of poultry (e.g. chickens or chicks).

Request information

Have you purchased a crate washer to wash a certain number of crates per hour or per day, but your business is growing? A crate washer can be expanded at any time in the future. However: there is a ‘but’ here.

Adding to a crate washer requires a considerable ‘alteration’ of the machine. So expanding a crate washer is also time-intensive and a relatively big investment. Learn more about increasing the capacity of the crate washer.

Do you want a no-obligation discussion about practical provisions that you can implement within your company? Then schedule an appointment with me.